C. acetobutylicum and the ABE fermentation process continued to be widely used until the 1950s when they were replaced by cheaper petrochemical-based processes, but it is getting a resurgence in biofuels research. With the addition of a metal catalyst, researchers have shown that the production of acetone, butanol and ethanol from lignocellulosic biomass could be selectively upgraded to the high volume production of gasoline, diesel or jet fuel.

Using the bacterium, researchers fermented the sugars found in biomass and then catalyzed those low carbon number products with the transition metal palladium into higher-molecular-mass hydrocarbons that are possible precursors to the three major transportation fuel molecules. The specific type of fuel molecule produced – whether a precursor to gasoline, diesel or jet – was determined by the amount of time the ABE products resided with the palladium catalyst.

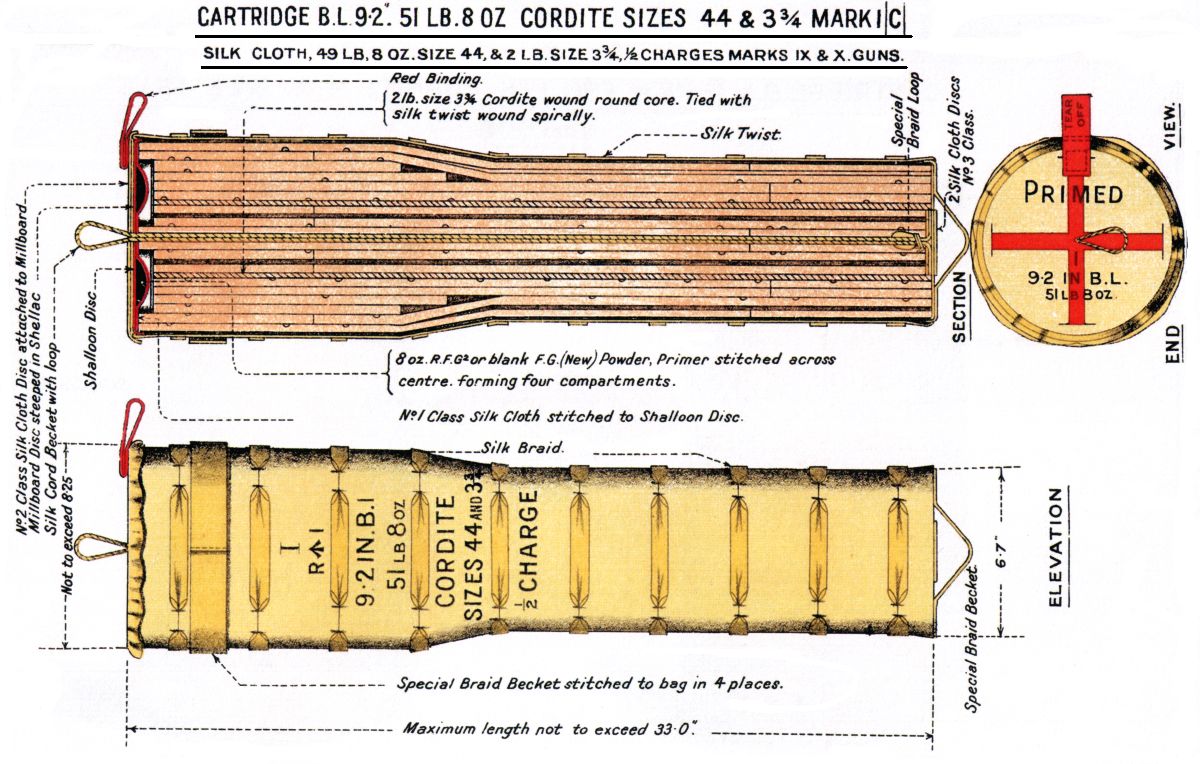

Clostridium acetobutylicum process once used to make cordite for artillery shells could now be a part of our biofuel future. Credit: LBNL

Current biofuels are not very good but the idea merits basic research funding even if subsidies and mandates are an economic and environmental negative. Synthesized from the sugars in the lignocellulosic biomass of grasses and other non-food plants, and produced in a sustainable manner, advanced biofuels could be carbon-neutral and still be a potential source of domestic jobs and revenue. Unlike ethanol made from corn starch or sugarcane, advanced biofuels developed and produced cost-effectively could be used today’s vehicles without the drop in performance ethanol brings.

“In some ways, this work is a step back in time in which a very old fermentation process is being used with some new engineering and chemistry,” says co-author of a new paper Harvey Blanch of Lawrence Berkeley National Lab. “While there has been some progress in engineering microbes to produce advanced biofuels, the quantities produced thus far – technically, the solution’s titer – tend to be very limited. A hybrid method, combining microbial production with chemical catalysis, might provide a pathway to more efficient production of these advanced biofuels.”

C. acetobutylicum ferments the sugars in lignocellulosic biomass into a product that is three parts acetone, six parts n-butanol, and one part ethanol, similar to how yeast ferments the sugars in grapes and hops into wine and beer (and biofuels from whisky waste in Scotland is on the research table too). From a transportation energy perspective, the two-carbon chains of ethanol, three-carbon chains of acetone and four-carbon chains of butanol are mainly useful as additives to gasoline. However, the production of acetone in combination with the alcohols makes it possible to build longer hydrocarbons chains of gasoline, diesel and jet fuel.

“The key to our technology is the ability of C. acetobutylicum to produce acetone,” says co-author Dean Toste, chemist with the Berkeley Lab. “Acetone harbors a nucleophilic alpha-carbon, which is amenable to the formation of carbon bonds with the alcohols produced in ABE fermentation.”

To catalyze the build-up of these shorter carbon chains into longer fuel chains – “alkylation” – the researchers tested a number of transition metal catalysts, the workhorses of modern industry that are used to initiate virtually every industrial manufacturing process involving chemistry. The best performer they tested was palladium.

“In the first reactor, we remove the low-boiling ABE products from the fermentation broth using a high-boiling extractant, such as glyceryl tributyrate,” Toste says. “This removes toxic products from the organism, allowing for higher yields of ABE and a clean stream of product for chemical catalysis, which takes place in a second reactor. While palladium on carbon was the best catalyst in these tests, we have already identified other transition metal catalysts that could be even better.”

Toste believes that the integrative biological/chemical approach he and his colleague are reporting should be relatively simple to scale-up and implement on a commercial scale.

“The ABE fermentation process was established and scaled nearly a century ago,” he notes, “and while the chemistry portion is less proven on scale, it relies on heterogeneous catalysis, a mainstay of industrial chemistry today.”

Toste believes the combination of biological fermentation and chemical catalysis has important potential applications beyond the conversion of lignocellulosic biomass into transportation fuels and could become a powerful new technology-enabling tool.

“Many technologies today rely on either fermentation or chemical catalysis,” he says. “The idea of building integrated fermentation processes involving networks of catalysts is an exciting prospect.”

From a news release written by Lynn Yarris at LBNL.

Citation: Pazhamalai Anbarasan, Zachary C. Baer, Sanil Sreekumar, Elad Gross, Joseph B. Binder, Harvey W. Blanch, Douglas S. Clark&F. Dean Toste, 'Integration of chemical catalysis with extractive fermentation to produce fuels', Nature 491, 235–239 doi:10.1038/nature11594

Comments