When it comes to environmental safeguarding, governments and public authorities spend most of their time in developing large programs. However by doing so, they often do not take into consideration minor concrete solutions that, if systematically taken, would reduce pollution emissions.

For example, I have long wondered why the American Federal Agencies or the European Community do not plan nor lay down new compulsory requirements to be fulfilled in the manufacturing of consumption goods, instead of allowing complete freedom in the use of materials, sizes and typologies. As a matter of fact, so far public authorities have done nothing but forbid - sometimes even after sale to consumers - the production of goods containing substances or materials considered to be harmful or dangerous by the international community. Some well-known cases are the ban of asbestos in fireproof products, of chlorofluorocarbons CFCs in refrigerators, of perfluorooctanoic acid PFOA in nonstickpans, and so on.

Moreover, an aspect which has been hitherto underestimated is the “indirect” pollutant effect of consumption goods, which can be caused by difficulties in waste separation and disposal or by the waste of energy and of resources employed during manufacturing, distribution and recycling.

Therefore, this “productive freedom” devoid of any standard of reference may increase the environmental contamination caused by some products. By contrast, these products may be produced, used and recycled in a more ecological way.

Ecological standards derive from deep studies

It is acknowledged that freedom in invention, production and sale of goods is the basis of economic development and democracy. However, there are some exceptions to this principle:

1) If a size, material or technology standard is laid on those who want to sell a certain product, this imposition does not prevent anyone from inventing or proposing for that product any other compatible or additional feature. For instance, a “P225/55R15”-sized tire must be built according to precise measurements, but this does not restrain producers from competing among themselves in terms of different performances and tread designs;

2) Throughout recent years there has been a growing awareness of the world’s public opinion toward policies aimed to reduce pollution and restrictions concerning the quality of products and production modes that are noxious or dangerous for human health and for the environment. Thereby, the market is now ready to accept policies for a stricter regulation of product sizes, materials and features, without running any risk of drop in consumption;

Actually, market globalization is currently prompting a greater standardization. However, in case of standards taken by enterprises on their own initiative, there is often a gap between economic optimization and environmental safeguarding. That is to say, the manufacturing of a specific size or material product in countries such as the China and the US guarantee a wider sale market and optimizes waste recycling and disposal, even though the size or material chosen might not be the best ones for environmental impact.

Interoperability lets standards reduce pollution.

There are industries where standardization is more developed and thus environmental protection is better performed. For example, in the auto industry standards are increasingly widespread and they make possible optimizations not only in chains for waste recycling and disposal, but also in the use of replaceable and reusable parts and accessories.As a matter of fact, even many years after a car is out of production, it is possible to find spare parts necessary to make it work, such as bulbs, batteries, tires and filters. This availability of spares on the market is accounted for by standardization – that is these parts are common to different car brands and models - which generates a market demand high enough to make up for the continuation of their manufacturing.

Nevertheless, there are industries where economic globalization has not brought about any advantage yet. This is a warning, especially for large consumption industries where the effect of any improvement of the product may be multiplied by millions of units.

Nevertheless, there are industries where economic globalization has not brought about any advantage yet. This is a warning, especially for large consumption industries where the effect of any improvement of the product may be multiplied by millions of units.Good news: a universal charger for mobile phones

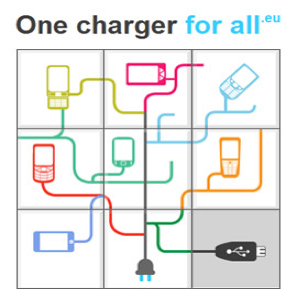

Thankfully, the European Union (UE) has launched a sign of improvement. Indeed, it has compelled the 14 main mobile phones manufacturers - accounting for 90% of products sold in the 27 member states of the EU- to adopt the same size standard for a universal battery charger from 2011 on.It is estimated that in the EU today there are about 500 million mobile phones and that every year 185 million new mobiles, varying in models and sizes, and using 30 different types of battery chargers, are sold. This deregulation reached such a high level of nonsense that two models of the same brand had two different incompatible chargers. So, anytime people bought a new mobile phone - though of the same brand -, they could not use the charger they already possessed. As a result, 51,000 million tons of electronic waste per year was generated in the EU alone.

After two years of pressure by the EU, the main manufacturers of mobile phones signed a Memorandum of Understanding. This document has established that from the first months of 2011 any “data enabled” mobile - including smartphones - must be compatible with a universal chargerwith “micro USB” connector.

After two years of pressure by the EU, the main manufacturers of mobile phones signed a Memorandum of Understanding. This document has established that from the first months of 2011 any “data enabled” mobile - including smartphones - must be compatible with a universal chargerwith “micro USB” connector.

It is a charger which must be produced according to the new harmonized EN 301489-34 EN 62684 standards, set by the following European standardization organizations, under mandate of the European Commission:

- The European Telecommunications Standards Institute (ETSI) developed all standards concerning safety risks and electromagnetic emissions and ensured that common chargers have sufficient immunity to external interference;

- The European Committee for Electrotechnical Standardization (CEN-CENELEC) established all standards regarding interoperability, i.e. compatibility of the common charger with data-enabled phones of different brands;

After this important initiative has been taken, we hope that the International Electrotechnical Commission may soon adopt the CENELEC standard on interoperability specifications of common external power supply (EPS) as an international standard.(Source: http://www.onechargerforall.eu/en/) The 14 companies which have joined the agreement (MOU) are: Apple, Emblaze Mobile, Huawei Technologies, LGE; Motorola Mobility, NEC, Nokia, Qualcom, Research in Motion (RIM), Samsung, Sony Ericsson, TCT Mobile (ALCATEL), Texas Instruments and Atmel.

The 14 companies which have joined the agreement (MOU) are: Apple, Emblaze Mobile, Huawei Technologies, LGE; Motorola Mobility, NEC, Nokia, Qualcom, Research in Motion (RIM), Samsung, Sony Ericsson, TCT Mobile (ALCATEL), Texas Instruments and Atmel.

Even though some small manufacturers have not joined, it can be easily foreseen that the “virtuous” development of the European market demand will shortly push them to conformation in order not to disappear.

Indeed, the new universal charger, besides reducing pollution, will improve life quality by means of letting anyone who is out of home with his discharged mobile phone borrow a charger from the friend putting him up or from the employer in the office he is in.

Additionally, it will be sold separately and in the course of time it will make possible the sale of mobiles without chargers, producing savings for consumers.

New universal charger with micro-USB connector

My personal expectation is that this innovative proposal might encourage national and international governments and institutions to increase initiatives for the definition of compulsory standards, which would lead to important environmental benefits in the market of large consumption goods.

High Pollution from single-used household batteries

We can start by taking as an example the pollution generated by the widespread consumption of house hold batteries – also known as “dry cell batteries” - used in cameras, toys, flashlights, radios and small electrical devices.

Household batteries are recycled in a much smaller ratio than lead acid batteries – also called “vehicular batteries”. As a matter of fact, lead acid batteries are all rechargeable and, therefore, have a long-life cycle. Additionally, they are heavy and bulky and cannot be easily disposed in the environment.

Household batteries are recycled in a much smaller ratio than lead acid batteries – also called “vehicular batteries”. As a matter of fact, lead acid batteries are all rechargeable and, therefore, have a long-life cycle. Additionally, they are heavy and bulky and cannot be easily disposed in the environment.

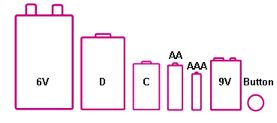

On the other hand, household batteries – also named “primary batteries” - are much smaller and lighter, are mostly manufactured in the “single-use” or non rechargeable sizes and, therefore, have a short-life cycle and are often disposed in the environment or thrown out in undifferentiated household litter. They include: alkaline and carbon zinc (in the international sizes labeled “9-Volt”,“D”, “C”, “AA”, “AAA”), mercuric-oxide (button cylindrical and rectangular, silver-oxide and zinc-air (button) and lithium (“9-Volt”, “C”, “AA”, coin, button) batteries. For further information on batteries please see the specific and clear guide drawn up by the US Department of Justice in 1997 and available in PDF format at: http://www.ncjrs.gov/pdffiles/172868.pdf

For further information on batteries please see the specific and clear guide drawn up by the US Department of Justice in 1997 and available in PDF format at: http://www.ncjrs.gov/pdffiles/172868.pdf

The most common sizes of household batteries.

Billions of household batteries every year

Worldwide, every year billions of household batteries – also called “portable batteries”- are sold, used and put into the litter cycle. Since portable batteries have a high environmental disposal and need a massive consumption of energy for recycling, they can be rightfully considered as a serious source of pollution.

In the US, according to the Environmental Protection Agency (EPA), every year three billion dry cell batteries are sold and, on average, each inhabitant consumes eight batteries per year. “….Batteries contain heavy metals such as mercury, lead, cadmium, and nickel, which can contaminate the environment when batteries are improperly disposed of. When incinerated, certain metals might be released into the air or can concentrate in the ash produced by the combustion process…” (Source: http://www.epa.gov/osw/conserve/materials/battery.htm).

By dividing the 308 million US inhabitants by the 3 billion portable batteries sold, the result is a yearly per capita consumption of 10 household batteries. However, the EPA estimates that 1 out of 5 batteries sold is a secondary battery and, thus, it can be deduced that the annual consumption estimated at 8 batteries per person refers to primary batteries.

Batteries, ground before incineration

According to the European Parliament, every year about 160,000 tons of portable batteries are put in the EU market, but the recycling of household batteries is still lacking. In 2002 almost half of this dangerous litter was still disposed of in incinerators or garbage dumps.

In 2006, the European Parliament approved a directive according to which schemes for the collection of spent portable batteries and accumulators must be adopted by 2008 in order to recycle collected batteries. The new directive also laid down minimum collection rates to be reached by all Member States: 25% by 2012 and 45% by 2016

In 2006, the European Parliament approved a directive according to which schemes for the collection of spent portable batteries and accumulators must be adopted by 2008 in order to recycle collected batteries. The new directive also laid down minimum collection rates to be reached by all Member States: 25% by 2012 and 45% by 2016

Do collection and recycling of spent batteries really solve the problem?

It is certainly important that governments succeed in laying down strict rules for massive recycling of household batteries in any country. Nevertheless, in my opinion, it is also necessary to carry out actions aimed at massively reducing the production of battery wastes since the recycling of batteries requires a lot of energy and, thus, it does not completely remove pollution problems.

For “D”, “C”, “AA”, “AAA” (with a single electrochemical cell) and “9-Volt” (with 6 cells) standard sizes, rechargeable batteries – also known as “secondary batteries”- have been on the market for a long time. These batteries were originally nickel-cadmium Ni-CD manufactured, whereas nowadays they are made mainly of nickel hydride NiMH a less dangerous and better performing compound that lets them be recharged up to 300-500 times.

Consequently, in past years a few factories decided to manufacture electronic devices with a multiple of 1.2 Volts-voltage, powered by rechargeable batteries (except some models of cordless phones), because they were bought only by a niche of consumers who watched out for energy savings and environmental impact.

Consequently, in past years a few factories decided to manufacture electronic devices with a multiple of 1.2 Volts-voltage, powered by rechargeable batteries (except some models of cordless phones), because they were bought only by a niche of consumers who watched out for energy savings and environmental impact.

Despite after a few use cycles, the voltage of a primary battery drops below 1.5 Volts per cell - decreasing at the same voltage as a secondary battery (1.2 Volts per cell) - the use of secondary batteries used to be inadvisable in devices not intended for them. Indeed, in those cases producers’ warranties did not cover any possible breakdown caused to electric circuits.

Rechargeable batteries reduce consumption and pollution

Maybe stimulated by the demand growth of rechargeable batteries, several companies have shown for some yearsthat the manufacturing of electronic devices which can be powered by either 1.5 and 1.2 Volts or their multiples – that is both primary and secondary batteries can be used – is not only technically possible but also economically compatible. As a matter of fact, the production costs of these devices areamortized by their market price.

Moreover, new universal chargers are now available in the market for D, C, AA, AAA and 9-Volt standard sizes. They use solar energy, thus avoiding the emission of that small quantity of pollution generated by chargers exploiting household electric energy produced by non-renewable sources.

Moreover, new universal chargers are now available in the market for D, C, AA, AAA and 9-Volt standard sizes. They use solar energy, thus avoiding the emission of that small quantity of pollution generated by chargers exploiting household electric energy produced by non-renewable sources.

Rechargeable batteries with solar energy charger

It is also thanks to the development of house hold secondary batteries characterized by an increasing charge capacity that digital cameras, flashes, flashlights and toys able to be powered by both primary and secondary batteries in standard sizes are now offered for sale. In addition to a greater charge capacity, these devices show some advantages if compared with those only using primary batteries:

1) a saving in operating costs of the device, thanks to the use of low–cost secondary batteries manufactured in large consumption sizes and rechargeable hundreds of times;

2) an environmental benefit due to the massive reduction of waste deriving from spent primary batteries.

In addition, this kind of device also highlights further advantages in comparison with those powered only by secondary batteries (i.e. batteries manufactured in exclusive sizes for each specific product):

3) a greater logistical autonomy. Indeed in case of emergency, when secondary batteries are discharged and there is no possibility to recharge them, primary batteries can be purchased everywhere;

4) an economic and environmental savings. A matter of fact, the device does not have to be replaced with e new one in case its specific size batteries are not available anymore on the market.

The EPA also confirms that “…One way to reduce the number of batteries in the waste stream is to purchase rechargeable batteries. Nearly one in five dry-cell batteries purchased in the United States is rechargeable. Over its useful life, each rechargeable battery may substitute for hundreds of single-use batteries.”

The EPA also confirms that “…One way to reduce the number of batteries in the waste stream is to purchase rechargeable batteries. Nearly one in five dry-cell batteries purchased in the United States is rechargeable. Over its useful life, each rechargeable battery may substitute for hundreds of single-use batteries.”

(Source: http://www.epa.gov/osw/conserve/materials/battery.htm ).

Billions of portable primary batteries are still manufactured in the world

I have wondered for many years why no government or any institution has ever thought about the possibility of adopting a simple solution. It would consist in placing on the manufacturers of electric and electronic devices a production standard compatible with rechargeable batteries. Indeed, although rechargeable batteries have been offered for sale for more than thirty years, there are still many devices or toys powered by non-rechargeable or primary batteries only.

By consulting the data published on UNDATA – website of the United Nations Statistic Division –, I calculated that the 14 world major manufacturer countries in 2006 sold 8,782 billion primary batteries, of which more than 60% in Japan. (Source: http://data.un.org/Data.aspx?d=ICS&f=cmID:46410-0).

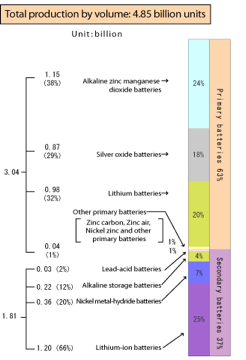

Besides, according to the statistics on the Japanese production published by the Battery Association of Japan (BAJ), in 2010 the manufacturing of household batteries was still composed of 63% of non-rechargeable primary batteries (Table 1).

Table 1: Japanese total production of household batteries in 2010

The BAJ also made public its estimate about the demand of primary batteries in Japan, according to which there will be a constant drop in demand of primary batteries in Japan (Table 2) and a steady growth in demand of secondary batteries in the world (Table 3).

Table 2: Portable primary battery demand forecast in Japan (Unit: million pcs.)

- These forecasts are BAJ estimates

- These forecasts cover shipments in Japan and imports (batteries built into equipment excluded)

Table 3: Global demand forecast for small secondary batteries (Unit: million pcs.)

- These forecasts are BAJ estimates

- These forecasts cover batteries for consumer products (HEV batteries excluded)

An example of the average saving of batteries achievable through rechargeable batteries

In order to foresee the ecological saving achievable by a certain country through there placement of all used primary batteries with secondary batteries, it is needed to know the average number of portable electrical device per capita. However, statistics or estimates on this aspect have not been found.

Nonetheless, by extracting from the available sources data about per capita consumption of primary batteries and by hypothesizing a minimum and a maximum threshold of duration of these batteries to power devices, it can be calculated with good approximation the minimum and maximum range of saving of batteries reachable through the sole use of rechargeable batteries.

The world’s leading consumer of portable batteries is Japan. Since in 2010 its population was about 127 million inhabitants, by using the data contained in Table 2 (consumption of primary batteries in 2010= 2,561 million pieces), it can be calculated that in 2010 the yearly per capita consumption was more than 20 batteries.

On the other hand, as it has been accounted above, the EPA estimated that the US annual per capita consumption was 8 batteries.

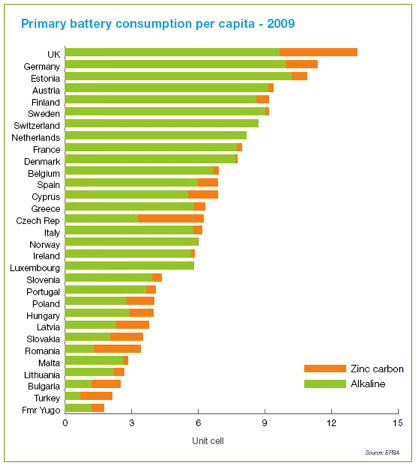

The European Portable Battery Association (EPBA) indicated in its 2010 Sustainability Report data relating to per capita average consumption of primary batteries percountry (Table 5). By multiplying the average consumption of each country in the EU by the number of its inhabitants, I have obtained the total of batteries consumed in each country. Then, by adding the national totals of the 27 member states, and by dividing the result by the inhabitants of the EU, I have got the yearly average per capita consumption of primary batteries in 2009, amounting to about 7 units.(Source: http://www.epbaeurope.net/Sustainabilityreport.html).

Table 5: Average per capita consumption of primary batteries

Besides, it is useful to consider that a portable device is more frequently powered by only one “6-Volt”, “9-Volt” or “button” size battery or from one to four “C” or “D” size batteries. On the other hand, in case of “AA” and “AAA” sizes, devices usually need two batteries and only rarely one or four.

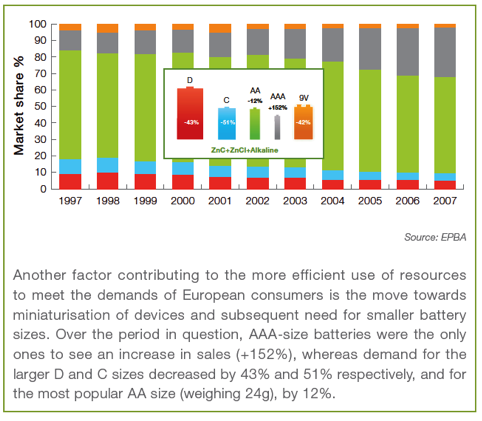

As the EPBA statistics indicate that in Europe “AA” and “AAA” sizes account for 80% of the consumption of primary batteries (see Table 6), I have assumed this datum is valid for the other world markets as well. So, I have supposed for the simulation an average use of two batteries for each portable device owned by each inhabitant.

Table 6: Sizes of primary batteries shared in the European market

However, the duration of batteries varies for each device according to its different use and its electric power. For instance, a button battery in a watch can last 5 years, while 2 batteries can last 12-24 months in a remote control, for 1,000-2,000 photos in a camera and for only a few hours in a toy or in a flashlight.

Despite the fact that the duration of batteries can vary considerably, I have verified that by calculating two simulations, one on the maximum and the other on the minimum threshold of duration, the two results obtained indicating the possible saving of batteries are very close to each other. So, it can be considered a reliable estimate.

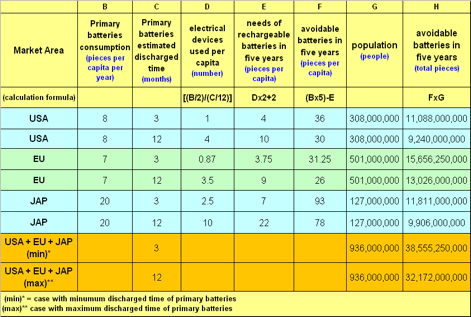

Therefore, I have examined the two possible combinations of minimum and maximum discharge time of primary batteries and the subsequent average number of electronic devices used per capita. In this way, I have calculated for each case an estimate of the total requirement of secondary batteries needed to completely replace primary batteries and the saving of batteries obtainable every five years (Table 7). For this estimate I have assumed that:

- A rechargeable battery has a life cycle which is no longer than 5 years (conservative);

- For the requirement of rechargeable batteries per inhabitant every five years, I have estimated two batteries for each electronic device plus two batteries to be stored up;

- For the estimate of the consumption of batteries avoidable in five years, I have multiplied the 2010 yearly consumption of primary batteries by five and I have subtracted the requirement of rechargeable batteries needed to replace them.

Table 7: Estimated saving of batteries in the USA, EU and Japan

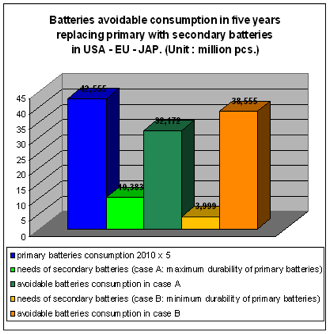

So, this simulation highlights that the replacement of the 8,500 million primary batteries consumed in 2010 with rechargeable batteries may save the consumption of about 32-39 billion batteries in a period of five years in the USA, Europe and Japan alone. Moreover, world-wide this number can be doubled and it represents a ratio of reduction in the consumption of batteries accounting for 75%-90% (Table 8).

Table 8: Estimated avoidable consumption of batteries in the USA, EU and Japan

A small big solution: the obligation to produce only rechargeable batteries in standard sizes

To sum up, it would be important that the EU, the US Federal Agencies and the public authorities of any country may institute –though gradually – new manufacturing standards for portable electronic devices, so as to allow them (including mobile phones) to be powered by standard size rechargeable batteries. In addition, at the same time, the planning and manufacturing of devices exploiting exclusive and size batteries should be forbidden.

Conclusions

- Globalization prompts standardization;

- Non-regulated standardization does not always bring about the best effects for the environment;

- The imposition to manufacturers of standards to improve environmental impact does not damage the market;

- The universal charger for mobile phones developed in Europe demonstrates that standards imposed by governments can be successful;

- Portable batteries are a serious source of pollution;

- The consumption of portable non-rechargeable batteries is still widespread and its trending decline is too slow;

- The technology of rechargeable batteries has reached the same performance level as that of primary batteries;

- The replacement of primary batteries can be quickly realized by means of instituting new manufacturing standards, compatible with standard size (9V – C – D – AA- AAA) rechargeable batteries for all portable electronic devices;

- The replacement of primary batteries with rechargeable batteries would reduce the global demand of portable batteries by 75 - 90%.

1st June 2011

Enrico Dorigo

Comments