Materials researchers at the National Institute of Standards and Technology (NIST), together with colleagues from IBM and the Massachusetts Institute of Technology, have pushed the measurement of thin films to the edge—literally—to produce the first data on how the edges of metallic thin films contribute to their magnetic properties. Their results may impact the design of future nanoscale electronics.

Ferromagnetic thin films of metallic materials—ranging in thickness from fractions of a nanometer to several micrometers—are layered in patterns on a substrate (such as silicon) during the manufacture of many microelectronic devices that use magnetic properties, such as computer hard drives.

While methods for measuring the magnetic properties of ferromagnetic thin films have existed for some time, there currently is no way to define those properties for the edges of the film. On a relatively large-scale device, this doesn’t matter much. However, as microelectronic components get smaller and smaller, the edge becomes a bigger and bigger fraction of the surface, eventually becoming the thin film’s dominant surface and the driver of its magnetic character. (Shrink a disk by half and the top surface area is reduced by a factor of four while the length of the edge is only halved.)

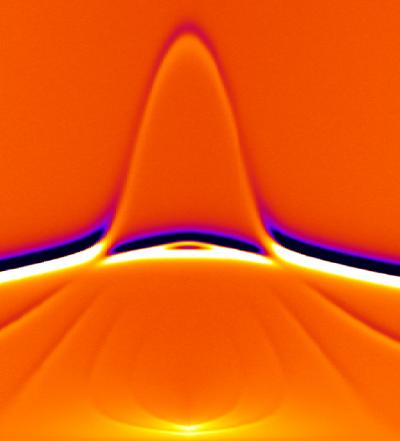

A research team from NIST, IBM and MIT recently demonstrated a spectroscopic technique for measuring the magnetic properties of the edges of nickel-iron alloy thin films patterned in an array of parallel nanowires (called “stripes”) atop a silicon disk. The researchers beamed microwaves of different frequencies over the stripes and measured the magnetic resonances that resulted. Because a thin film’s edge resonates differently from its center, the researchers were able to determine which data—and subsequently, which magnetic behaviors—were attributable to the edge.

In its first trials, the new technique has been used to measure how the magnetic properties of the thin film edge are affected by the thickness of the film and the processing conditions during the stripe patterning. Data gained from the study of stripes with widths of 250 to 1,000 nanometers will be used to predict the behavior of similar structures at the nanoscale level (100 nanometers or less).

- NIST

Comments