In this article a combination of known facts and Newtonian mechanics is used to show that the most probable cause of the tragedy was a software fault. Evidence is submitted which shows that the fuel was cut off by the aircraft's automated control systems and the switches were afterwards moved by a pilot as a perfectly proper corrective action.

Simplicity Versus Complexity

In science there is a principle called Occam's Razor1 which, in simple terms, states that a simple causal explanation of a phenomenon is more likely to be true than a complex one. An Occam-compliant hypothesis about a phenomenon must incorporate only such explanatory conditions as are sufficient and necessary. The flip side of Occam compliance is the construction of a complex chain of causation by way of explanation.

A Complex Hypothesis

Many videos on the YouTube channel Airline News with Geoffrey Thomas2, joined by Richard Godfrey, claim to have discovered the probable cause of the Air India 171 tragedy. The claim is made that smoke from a lithium-ion battery is seen in the airport surveillance footage. A claim is made in support of a battery fire that the damage to the aft flight recorder is greater than that which is to be expected from impact and post-accident fire. The claim is made that the proximate cause of the chain of events is water ingress into the aft electronics bay and the battery. From these assumptions, a chain of hypothetical events is constructed which is then submitted to viewers as the probable cause of the tragedy. There is a far simpler explanation of this tragic accident: a far more probable cause.

A Simple, Science-based Hypothesis

There is a simple explanation of this accident based in the laws of physics, more specifically Newtonian mechanics. The sequence of events in the AI 171 accident can be explained in simple terms of motion, momentum and kinetic energy. This Occam-compliant sequence demonstrates the most likely time of initial fuel cutoff.

Newton's Laws Of Motion

Newton's laws of motion are three physical laws that describe the relationship between the motion of an object and the forces acting on it. These laws, as applied to an aircraft in flight, can be paraphrased in terms of the most basic physics of flight.

Thrust, Drag, Lift, Weight

Newton's 1st law - An aircraft remains in motion at a constant speed and altitude unless it is acted upon by a force.

The speed of an aircraft in horizontal flight is determined by the force of thrust minus the force of drag.

The altitude of an aircraft in horizontal flight is determined by the force of lift minus the force of gravity.

The rate of altitude change of an aircraft is determined by the combined forces of momentum, thrust and lift, opposed by the combined forces of drag and weight

Fuel Cutoff In High Bypass Turbines

The B787 is ETOP certified for 1 engine operation for 330 minutes. It is also certified as able to continue taking off with one engine after V1, subject to a limit of 10 minutes at maximum continuous thrust. The engines of VT-ANB were high bypass turbines with a bypass ratio of 9:1. This means that 90% of thrust is due to the fans and only 10% is due to the turbojet engine. If one engine fails during the takeoff roll after V1 the takeoff can be continued on the remaining engine. Put another way, 50% of combined maximum permissible thrust is sufficient to achieve a safe takeoff after V1.

At the moment of fuel cutoff to both engines during takeoff the combined thrust will be instantly reduced to 180% of selected thrust. The aircraft will continue to accelerate and rise until the combined thrust is below 50% of selected thrust. This will arise when the thrust of each engine has dropped to below 25%.

The Timeline Of Key Events

These times are derived from the AAIB Preliminary Report3.

08:07:37 - Aircraft commenced takeoff roll.

08:08:33 - Aircraft achieved 153 kts IAS - V1

08:08:35 - Aircraft achieved 155 kts IAS - VR

08:08:39 - Air/ground sensors transitioned to air mode.

08:08:42 - Aircraft achieved maximum recorded airspeed of 180 Knots.

?? - Switches moved to cutoff.

08:08:47 - RAT began supplying hydraulic power. (approximate time)

08:08:52 - Engine 1 fuel cutoff switch transitioned from CUTOFF to RUN.

08:08:54 - APU Inlet Door began opening. (approximate time)

08:08:56 - Engine 2 fuel cutoff switch transitioned from CUTOFF to RUN. (approximate time)

08:09:11 - FWD EAFR recording stops.

When fuel control switches are moved from CUTOFF to RUN while the aircraft is inflight, each engines full authority dual engine control (FADEC) automatically manages a relight and thrust recovery sequence of ignition and fuel introduction.

The movement of the switches implies the need to relight, hence it implies prior flameout.

Fuel cutoff, screenshot from AAIB report

The phrasing of the fuel cutoff sequence in the AAIB Report3 implies, but does not state, that the fuel was cut off as a result of switch movement. The report appears to avoid specifying the true sequence of events, a truth supported by Newtonian mechanics as applied to aircraft.

In the following quote, N1 is the fan speed, N2 the high pressure spool speed and EGT is Exhaust Gas Temperature.

The Engine N1 and N2 began to decrease from their take-off values as the fuel supply to the engines was cut off.Maximum Speed After Fuel Cut Off

...

When fuel control switches are moved from CUTOFF to RUN while the aircraft is inflight, each engines full authority dual engine control (FADEC) automatically manages a relight and thrust recovery sequence of ignition and fuel introduction.

The EGT was observed to be rising for both engines indicating relight. Engine 1’s core deceleration stopped, reversed and started to progress to recovery. Engine 2 was able to relight but could not arrest core speed deceleration and re-introduced fuel repeatedly to increase core speed acceleration and recovery.

The maximum speed specified in the AAIB report must have been achieved some seconds after the fuel was cut off. A turbofan does not lose thrust instantly when fuel is cut off: the fan continues to produce useful thrust for some time due to rotational inertia aka the flywheel effect.

The recorded time 08:08:42 is the point at which the residual thrust was insufficient to further accelerate the aircraft. At 08:08:39 - Air/ground sensors transitioned to air mode. The difference in time is 3 seconds.

Expert advice is needed here, but it would seem that the residual thrust would decay fairly rapidly: 3 seconds appears to be a too low ballpark figure. The rpm would reduce as thrust energy was used in vertical and horizontal acceleration and in the provision of electrical power. The fuel must have cut off at 08:08:39 at the very latest. It appears to be more likely that the fuel was cut off before liftoff while the aircraft was still in ground mode, perhaps even 3 seconds before VR.

RAT Deployment

The AAIB preliminary report gives no time at which RAT deployment was triggered, but does state that the RAT began supplying hydraulic power at 08:08:47. Absent publicly available definitive data, the widely commented claim is relied on that the RAT takes 6 to 7 seconds to begin to supply hydraulic power and around 10 seconds to supply maximum electrical power.

From the times in the AAIB report -

08:08:39 - Air/ground sensors transitioned to air mode.

08:08:42 - Aircraft achieved maximum recorded airspeed of 180 Knots.

08:08:47 - RAT began supplying hydraulic power. (approximate time)

The RAT most likely deployed between 08:08:40 and 08:08:41. This is after liftoff and before maximum airspeed was achieved. The engines were not fully shut down and were still capable of delivering useful electrical power at this time. Absent any proof of another cause of electrical failure this leaves loss of hydraulic pressure as the most likely cause of RAT deployment. The hydraulic pumps on the 787-8 are electrical. It appears likely that selecting gear up placed an electrical load on the engines which could not be sustained, leading to loss of hydraulic pressure. The landing gear remained down because the RAT does not supply hydraulic power to raise it.

The APU Air Intake

Post crash images show the APU air inlet open to the in-flight angle. The ideal angle of opening was determined at the design stage to be 17 degrees in flight and 45 degrees on the ground. The angle of opening shown in the images does not support a claim that the APU start sequence was interrupted due to APU battery failure.

The Two Flight Recorders

Geoffrey Thomas and Richard Godfrey state that any rebuttal of their theories must explain the extensive damage to the aft EAFR as compared to the forward EAFR. That difference is readily explained in terms of kinetic energy, the energy of motion, together with the patterns of fire. No recourse to battery chemistry is necessary.

Newton's 2nd law - force = mass x acceleration. This equation conveys the rate at which the aircraft's momentum is changing with time. The shorter the time of positive or negative change in momentum, the greater the G force experienced; conversely, the greater the time, the lesser the G force experienced.

Newton's 3rd law - If an aircraft in motion makes contact with a stationary object the forces of impact have the same magnitude on the aircraft and the object.

Crumple Zones

Cars incorporate crumple zones to increase the distance over which momentum is dissipated. The greater the distance, the less the force of acceleration experienced by the occupants.

When any part of an aircraft is brought to rest in an accident it experiences a force of acceleration. The magnitude of further forces of acceleration is reduced as the product of the remaining mass and the square of the remaining velocity.

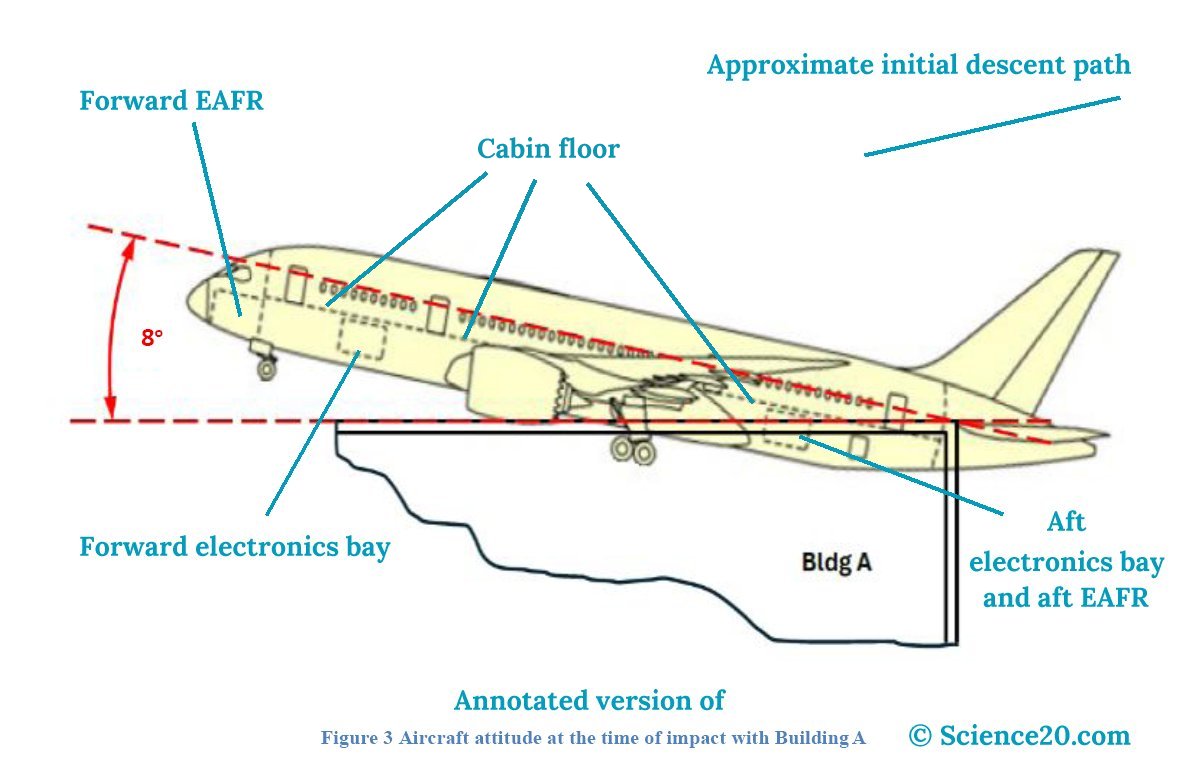

Impact On Building A

This AI-generated image from the AAIB preliminary report is annotated to show how the initial impacts reduced the velocity and mass of the remainder of the aircraft.

As the tail, landing gear, wings and fuselage parts came to rest the momentum of each remaining part was greatly reduced. The reduction in momentum of parts remaining in motion explains how the sole survivor was able to walk away. It also explains how the forward EAFR was subjected to minimal impact damage: it came to rest in the same area as the passenger's seat. Conversely, the aft EAFR was in the zone of initial impact. The fact that it was then brought to rest in a fairly short distance is consistent with a dramatic reduction in its velocity. The destructive forces acting on the aft EAFR were evidently orders of magnitude greater than the forces acting on the forward EAFR.

Post-accident Interior View Of Building A

The above image, sourced from NDTV4 shows quite clearly that the tail and the starboard main landing gear were brough to rest over a significant distance. A great amount of energy was obviously absorbed by the damage to the building and the aircraft.

EAFR Fire Damage

Post-crash Image Of Rooftop Fire

The rooftop photo sourced from EasternEye5 shows a limited area of fire damage near the engine. The bright area is likely from a camera flash. The aft EAFR was found to the left of the concrete slab as seen from this viewpoint. The aft EAFR catastrophic damage cannot have been caused by being in the relatively small fire zone.

Dust At Liftoff June 2024

In support of their battery fire claim, Geoffrey Thomas and Richard Godfrey insist that the swirling cloud seen at liftoff is smoke from a battery fire. In a previous article here6 it is shown that dust lofting by wake trubulence is a common ocurrence.

Dust Lofted By VT-ANB in June 2023

Further to this credible evidence of dust lofting, the YouTube channel Silver Wings 101 has published a video7 of VT-ANB taking off from Ahmedabad in June 2023, a year previous to the accident. Dust lofted by the aircraft can be clearly seen. The amount of dust lofted by aircraft at Ahmedabad airport will vary with the amount of vegetation cover, which will vary with the seasonal changes in weather and the degree of maintenance.

Prior Problems With Fuel Cut Off By Flawed FADEC Software

Geoffrey Thomas and Richard Godfrey claim that a dual engine FADEC fault is highly improbable. They discount the relevance of previous FADEC problems because those problems did not occur on the 787-8 GENx engines. FADECs are obviously manufactured and programmed to suit the specific requirements of different engines and aircraft but the underlying software logic remains the same. Accordingly, what has happened to other aircraft can also happen to a 787-8.

In a previous article here8 it was shown that "in January 2009 it was a known fact that a FADEC software fault could cause a dual engine shutdown on takeoff."

It is of no significance that this FAA DA concerns the 777 and that the Air India tragedy involved a 787. A FADEC is a computer which is programmed to optimise the fuel-air ratio depending on pilot thrust demand, altitude, air density, engine temperature, oil pressure and temperature and many other factors. The FADEC is also responsible for engine protection against damage which might be caused by operation outside of the designed parameters.On January 17, 2019 fuel to both engines of ANA Flight NH-985 was cut off on touchdown. That aircraft uses Rolls Royce engines.

Obviously FADECs are designed and programmed to match the engines with which they are to be used. But it would be a specious argument to say that FADEC problems on other aircraft have no bearing on what happened to Air India 171.

Air India Crash: Update #3

On July 11, 2021 fuel to both engines of an Air Baltic A220 was cut off on touchdown. That aircraft uses Pratt and Whitney engines.

In 1994 a Boeing Chinook crashed on the Mull of Kintyre. The initial reaction of the powers that be was to blame the pilot. It later transpired that there had been many problems with the FADEC.

Three of the four engines of an Airbus A400M experienced power frozen after lift-off and did not respond to the crew's attempts to control the power setting in the normal way.

Speyer, Germany. In March 2019 both engines on a DA42 Twin Star failed simultaneously as the pilot selected gear up. He was able to land immediately with no injuries. This was caused by a FADEC flaw which shut down both engines.

Summary

It is a known, indisputable fact that a FADEC problem can shut off fuel to engines. There is no valid reason to believe that a 787-8 with GE engines is somehow immune to FADEC problems which have affected other aircraft.

Of all the possible causes of the loss of AI 171, the simplest probable cause, not relying on a hypothetical chain of events, is software acting on flawed input data.

Footnote

I work on these articles alone and unpaid. Any errors in my articles are entirely down to me.

Sources

1 - Occam's Razor

https://en.wikipedia.org/wiki/Occam's_razor

2 - Airline News with Geoffrey Thomas

https://www.youtube.com/@geoffreythomas-on-air

3 - AAIB preliminary report

https://aaib.gov.in/What's%20New%20Assets/Preliminary%20Report%20VT-ANB.pdf

4 - NDTV plane crash pics

https://www.ndtv.com/india-news/ahmedabad-plane-crash-pics-show-crashed-...

5 - EasternEye crash images

https://www.easterneye.biz/experts-suspect-engine-failure-or-bird-hit-in...

6 -Air India Crash: Update #5 - It's Dust, Not Smoke

7 - Ahmedabad Air India Boeing 787 crashed, the same Aircraft Back in June 2023

https://youtu.be/qiJkCQzByYs?si=ER0WuuEajYsvoOFu

8 - Air India Crash: Update #3

Further information

SHOCKING |The Pilots Tried to SAVE the Airplane - With Proof

https://youtu.be/A99LSiAv4ws?si=eMIp0N_FbeTxWFTy

Powering the Dreamliner: How the 787's GEnx Engines Work

https://thepointsguy.com/airline/powering-the-dreamliner-how-the-787s-ge...

A long read in 3 parts

https://foundingfuel.com/article/ai-171-the-investigation-that-could-red...

Edit -

Transposition of words aft and forward corrected.

Minor typo corrected.

Comments