Why not a light-emitting fork?

Physicist Amir Asadpoordarvish of Umeå University in Sweden did just that, using new light-emitting electrochemical cells (LECs) sprayed onto a substrate that emit light using the current from an ordinary battery. A LEC is a solid-state thin-film device, which comprises an active material sandwiched between a cathode and an anode as its key constituent parts. To-date they have been fabricated on heavy, rigid parts.

In the paper, two different types of paper substrates are coated with a surface emitting light emitting electrochemical cell (LEC) device: a multilayer-coated specialty paper with an intermediate surface roughness of 0.4 μm and a low-end and low-cost copy paper with a large surface roughness of 5 μm.

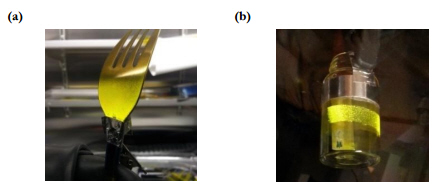

(a) A light-emitting fork, as realized by spray-sintering a stainless-steel fork with an active layer and a top cathode. (b) A light-emitting glass vial fabricated by an anode comprising Ag-NW/ZnO, an active layer and a top cathode layer spray-deposited on its outer surface. Link

The entire device fabrication was done using a handheld airbrush, and it is notable that all of the constituent layers are deposited from solution under ambient air.

The top-emitting paper-LECs are highly flexible, and display a uniform light emission with a luminance of 200 cd m−2 at a current conversion efficacy of 1.4 cd A−1.

Asadpoordarvish, A., Sandström, A., Larsen, C., Bollström, R., Toivakka, M., Österbacka, R. and Edman, L. (2015), Light-Emitting Paper. Adv. Funct. Mater. doi: 10.1002/adfm.201500528

Comments