Solar panels are easily susceptible to mechanical problems. Storms, leaves, you name it - but some of that is because they are rigid. That rigidity also limits their applications.

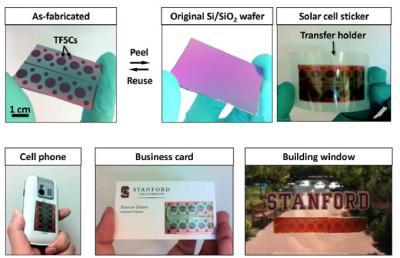

New flexible, decal-like solar panels that can be peeled off like band-aids and stuck to virtually any surface, from papers to window panes, could make solar power a lot more deployable. The world's first peel-and-stick thin-film solar cells have been created by researchers at Stanford University and unlike standard thin-film solar cells, their peel-and-stick version does not require any direct fabrication on the final carrier substrate.

Thin-film photovoltaic cells are traditionally fixed on rigid silicon and glass substrates, greatly limiting their uses. Thin-film solar cells bring some flexibility to the technology but alternate substrates are the way to go.

"Nonconventional or 'universal' substrates are difficult to use for photovoltaics because they typically have irregular surfaces and they don't do well with the thermal and chemical processing necessary to produce today's solar cells," says Xiaolin Zheng, a Stanford assistant professor of mechanical engineering and senior author of the paper. "We got around these problems by developing this peel-and-stick process, which gives thin-film solar cells flexibility and attachment potential we've never seen before, and also reduces their general cost and weight."

Utilizing the process, researchers attached their solar cells to paper, plastic and window glass among other materials - and didn't lose any of the original cell efficiency.

The Stanford peel-and-stick thin-film solar proces. Credit: Chi Hwan Lee, Stanford School of Engineering.

The new process involves a unique silicon, silicon dioxide and metal "sandwich." First, a 300-nanometer film of nickel (Ni) is deposited on a silicon/silicon dioxide (Si/SiO2) wafer. Thin-film solar cells are then deposited on the nickel layer utilizing standard fabrication techniques, and covered with a layer of protective polymer. A thermal release tape is then attached to the top of the thin-film solar cells to augment their transfer off of the production wafer and onto a new substrate.

The solar cell is then ready to peel from the wafer. To remove it, the wafer is submerged in water at room temperature and the edge of the thermal release tape is peeled back slightly, allowing water to seep into and penetrate between the nickel and silicon dioxide interface. The solar cell is thus freed from the hard substrate but still attached to the thermal release tape. They heat the tape and solar cell to 90°C for several seconds, then the cell can be applied to virtually any surface using double-sided tape or other adhesive. Finally, the thermal release tape is removed, leaving just the solar cell attached to the chosen substrate.

Tests have demonstrated that the peel-and-stick process reliably leaves the thin-film solar cells wholly intact and functional, Zheng said. "There's also no waste. The silicon wafer is typically undamaged and clean after removal of the solar cells, and can be reused."

While others have been successful in fabricating thin-film solar cells on flexible substrates before, those efforts have required modifications of existing processes or materials.

"Now you can put them on helmets, cell phones, convex windows, portable electronic devices, curved roofs, clothing – virtually anything," said Zheng. Moreover, peel-and-stick technology isn't necessarily restricted to thin-film solar cells. The researchers believe the process can also be applied to thin-film electronics, including printed circuits and ultra thin transistors and LCDs.

"Obviously, a lot of new products – from 'smart' clothing to new aerospace systems – might be possible by combining both thin-film electronics and thin-film solar cells," observed Zheng. "And for that matter, we may be just at the beginning of this technology. The peel-and-stick qualities we're researching probably aren't restricted to Ni/SiO2. It's likely many other material interfaces demonstrate similar qualities, and they may have certain advantages for specific applications. We have a lot left to investigate."

Published in Scientific Reports.

Comments