Researchers with the U.S. Department of Energy Joint BioEnergy Institute have identified the genetic origins of a microbial resistance to ionic liquids, based on a pair of genes discovered in a bacterium native to a tropical rainforest in Puerto Rico, and successfully introduced this resistance into a strain of E. coli bacteria.

Yes, it's Frankenfuel, but hopefully anti-science zealots won't make creating an abomination of nature that leads to less fossil fuels.

The burning of fossil fuels continues to release nearly 9 billion metric tons of excess carbon into the atmosphere each year to the detriment of global climate trends - and America stopped pursuing emissions-free nuclear energy during the Clinton administration so we have been essentially reinventing the wheel and embracing suspect alternative energy like ethanol since then. Yet advanced biofuels synthesized from the cellulosic biomass in non-food plants may represent a clean, green, renewable alternative to today's gasoline, diesel and jet fuels, though it is yet to be seen if they can avoid the protests associated the groups against biological and energy science.

JBEI researchers have previously engineered strains of E. coli bacteria to digest the cellulosic biomass of switchgrass, a perennial grass that thrives on land not suitable for food crops, and convert its sugars into biofuels and chemicals. However, the ionic liquids used to make the switchgrass digestible for the E.coli was also toxic to them and had to be completely removed through several washings prior to fermentation.

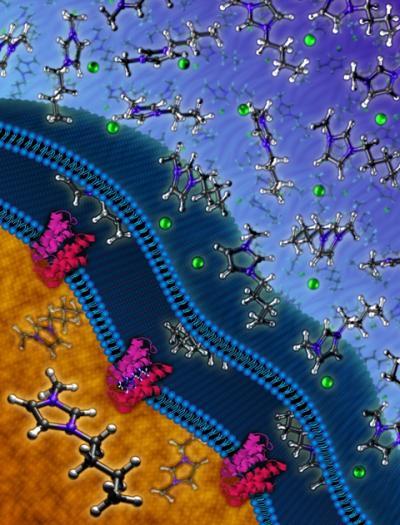

Joint BioEnergy Institute researchers identified the genetic origins of a resistance to ionic liquids found in Enterobacter lignolyticus, a soil bacterium discovered in a rainforest in Puerto Rico. Image courtesy of Michael Thelen, Joint BioEnergy Institute

"We identified two genes in Enterobacter lignolyticus, a soil bacterium that is tolerant to imidazolium-based ionic liquids, and transferred them as part of a genetic module into an E.coli biofuel host," says Michael Thelen, a biochemist with JBEI's Deconstruction Division. "The genetic module conferred the tolerance needed for the E.coli to grow well in the presence of toxic concentrations of ionic liquids. As a result, production of a terpene-based biofuel was enhanced."

Thelen, a senior investigator with DOE's Lawrence Livermore National Laboratory (LLNL), is the corresponding author of the paper "An auto-inducible mechanism for ionic liquid resistance in microbial biofuel production" in Nature Communications.

"The extensive washing required for complete ionic liquid removal is not feasible in large-scale, industrial applications," says Blake Simmons, a chemical engineer who heads JBEI's Deconstruction Division. "An ideal and more sustainable process is to balance the costs of removing the ionic liquid with the fermentation performance by using biofuel-producing microbes that can tolerate residual levels of ionic liquids."

Two years ago, JBEI researchers returned from an expedition to the El Yunque National Forest in Puerto Rico with the SCF1 strain of Enterobacter lignolyticus, which had shown a tolerance to high osmotic pressures of the sort generated by exposure to ionic liquids. A model was developed at JBEI in which the SCF1 bacteria are able to resist the toxic effect of an ionic liquid by altering the permeability of their cell membrane and pumping the toxic chemical out of the cell before damage occurs.

In this latest study, the JBEI researchers used a creative approach devised by lead author Ruegg to rapidly pinpoint the genes responsible for ionic liquid resistance in the genomic DNA of SCF1.

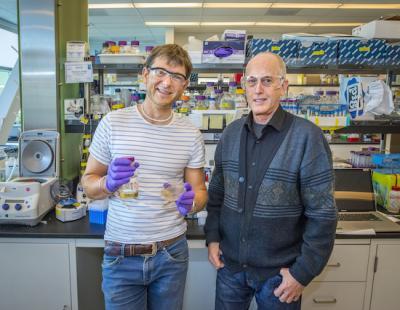

Thomas Ruegg (left) and Michael Thelen led a Joint BioEnergy Institute team that successfully introduced an ionic liquid resistance into a strain of E. coli for the production of advanced biofuels. Photo by Roy Kaltschmidt, Berkeley Lab

"This genetic module encodes both a membrane transporter and its transcriptional regulator," Ruegg says. "While the pump exports ionic liquids, the substrate-inducible regulator maintains the appropriate level of this pump so that the microbe can grow normally either in the presence or absence of ionic liquid."

The results of this study show a way to eliminate a bottleneck in JBEI's biofuels production strategy, which relies on ionic liquid pretreatment of cellulosic biomass. It also shows how the adverse effects of ionic liquids can be turned into an advantage.

"The presence of residual ionic liquids may prevent the growth of microbial contaminants, so that fermentation can proceed under more economical, aseptic conditions," Thelen says. "Our findings should pave the way for further improvements in microbes that will contribute to the sustainable production of biofuels and chemicals."

Comments