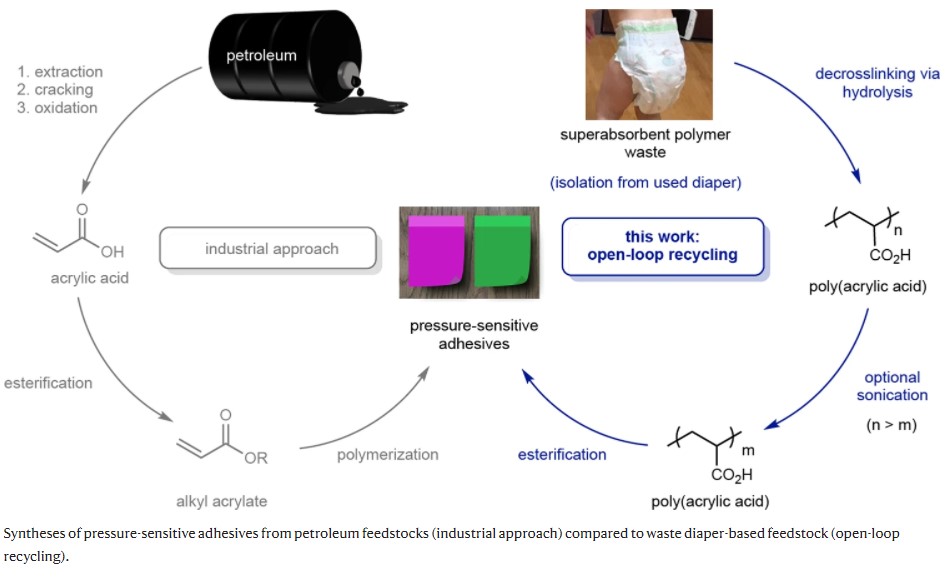

Diapers are not what you'd think about first when you consider recycling. The CBC estimates the number at billions of disposable diapers entering landfills in North America. With this much waste, recycling these absorbent plastics might seem like a good idea. The super-absorbent material inside diapers is made up of long-chain polymers. Unfortunately, they don't get put into recycling bins because the composition of these materials is too complex to break down and recycle traditionally. The problem with diapers is that we haven't found a way to recycle them into something useful. At least, until now. As we note, there are alternative means of recycling that are dealing with the shortcomings of traditional methods.

A paper published in Nature Communications proposes a method of recycling these long-chain polymers into something usable. The resulting compound is likely to be a sticky compound, like those you'd find on sticky notes. Initially, the polymers are designed to absorb liquid. When any sort of liquid hits them, they expand and absorb it. Of course, this absorption serves a practical purpose when used in a diaper, but it can also absorb quite a lot of rain when out in a landfill. Ideally, if we could recycle them, we could potentially clear massive areas of landfills that would otherwise be used to house sodden diapers.

That's why this discovery is so vital. To fully appreciate the groundbreaking nature of this advancement, we must first look at how recycling works and the processes involved in recovering materials from the trash to be reused.

Graphic: Chazovachii, P.T., Somers, M.J., Robo, M.T. et al. Giving superabsorbent polymers a second life as pressure-sensitive adhesives. Nat Commun 12, 4524 (2021). https://doi.org/10.1038/s41467-021-24488-9

Mechanical vs. Chemical Recycling

Most of us know about recycling from short films we saw in school. Most explanations of recycling, including those short films, tend to focus on the process of mechanical recycling. The basic premise is that plastics are separated by their type, chopped up into tiny pieces, then melted down and reused. The problem with mechanical recycling is that it can only be done so many times. The resulting product that comes from the process is of lower quality. The quality decreases with each successive recycle until the plastic is only reasonable to be tossed out. When we think about recycling, nobody mentions that the methods we use may have a finite amount of reuse before we have to discard them.

Chemical recycling is a more complex process but approaches the problem from a different angle. In chemical recycling, the compounds that make up a particular component are isolated to be reused as a similar product or recycled into something that offers just as much or more value. For plastics, this is good news. Because plastics are durable and malleable yet hard to break down or dissolve, recycling them mechanically is challenging. However, those same properties are what make plastics so desirable as a packaging material and all the uses we put it to today. These plastics are usually built out of long-chain polymers. Polymers are a type of plastic that demonstrates strong bonds between its molecules, giving them the material properties that we associate with plastics. With chemical recycling, we can take those plastics and turn them into another type of plastic without sacrificing usability yet without serious degradation between one product and another.

The Challenge of Super-Absorbent Polymers

When diapers were designed, their super-absorbent polymers weren't built to ever degrade. The aim was to have a plastic that would retain the water for as long as it existed. Recycling long-chain polymers like these is a challenge, even in chemical recycling. The polymers in these super-absorbent plastics look like a fishnet that's been loosely woven together. Between the layers, some crosslinks appear infrequently yet are enough to make the plastic insoluble. The scientists that worked on the problem realized that heating the layers broke down the crosslinks, making the plastic soluble and reusable. Once they made that breakthrough, they spent a while figuring out whether the process could be scaled up industrially. Next, they broke down the massive chains of polymers into something shorter. The shorter chains make them easier to manipulate to create a value-added substance. The final step was to change the compound's acid groups to ester groups, turning the material into a gooey compound like an adhesive.

The Future of Diaper-Adhesives

Is this process more efficient than current methods of recycling? Does it produce environmentally sustainable adhesives out of these diapers? Currently, the process for getting adhesives out of these diapers creates less global warming than conventional adhesives. Although, researchers note that this process used clean diapers. Used diapers, the ones we're most likely to be recycling, may need to be cleaned first. Companies already do cleaning or diapers, allowing them to be recycled, but that may add to the carbon footprint of the process. More research is needed before stating unequivocally that recycling diapers are the best way to make future adhesive products.

What are Coronal Holes

According to the UCAR Center for Science and Education, these holes are areas of the sun's atmosphere where the plasma is less dense than surrounding areas. In ultraviolet scans of the sun's surface, they appear darker in color because plasma particles can escape the sun's massive magnetic field, leaving the area a void. These escaping particles create a phenomenon known as the solar wind. When these solar winds buffet the Earth, they cause electronic malfunctions, poor reception, and a host of other issues. The amount and the frequency of holes in the sun's corona varies based on solar activity. Knowing when there are large holes in the corona is a warning for potentially violent solar winds.

It's Not As Simple as Looking

judging from the photographs of coronal mass-ejections, it might seem as simple as looking at the pictures to let you know there are coronal holes. Yet traditional algorithms, as well as human eyes, have had trouble distinguishing them from other areas of the corona. The coronal holes aren't the only dark areas in the sun's atmosphere, making it hard to pinpoint false positives. As with most issues that conventional algorithms have a problem with, the scientists decided to craft a bespoke neural network that would address the coronal hole problem directly. The result was CHRONNOS (Coronal Hole RecOgnition Neural Network Over multi-Spectral-data).

Typically, scientists would use extreme ultraviolet (EUV) images to spot the signs of coronal holes. The team trained the AI on previous pictures and let the AI define the coronal holes from 260 previously captured images. The accuracy at the end of testing was at 98.1% success. The neural network was at its best when both EUV and magnetic image data were included. However, if just presented with EUV images, the neural network could still accurately pinpoint the void areas in the pictures. Additional research showed that the observation period didn't matter since CHRONNOS could predict coronal activity over a short and long-term observation window. All of these combined allow CHRONNOS to pick out details from real-time solar maps.

Practical Applications of the Early-Warning System

The team thinks that this new technology can come in handy for warning us about upcoming solar mass-ejection events. With today's current warning system based on observation, we may get anywhere between seventeen and thirty-six hours of warning before a solar flare hits the Earth. They can wreak havoc on electronics and transmission systems because of the large volume of charged particles that make it into the atmosphere. Most of the radiation from these solar flares is stopped by the Earth's magnetic field, but many satellites that help us communicate are too far off the ground to benefit from this protection. Not only does coronal mass ejection affect telecommunication satellites, but they could also have a distinct impact on our ability to generate power on the ground.

The flare's peppering of the Earth's atmosphere can cause wires on the ground to behave strangely because of the charged atmosphere. This difference in behavior could cause disruptions on the power grid over a massive area. The US has an observation post in Hawaii dedicated to spotting the rise in chances of a coronal mass ejection. They call power companies when they see the threshold go above a certain level to warn them. This technology could improve their efforts significantly by giving them a more accurate way to spot these ejections coming.

Protecting Ourselves from External Threats

While we may not realize how much the sun's activity can impact our modern lives, that doesn't change the fact that it does. We've dealt with heavy solar storms before and come out relatively unscathed, but for the most part, we've been lucky. With such a small window in our current early-warning system, a minor inefficiency could spell disaster for a large portion of the population. This technology seeks to give us better tools to detect these problems before they occur. You shouldn't be staring at the sun with your browline glasses. Leave that to the AI - it's better trained to stare at the sun than you are.

New Research into Antiferromagnetic Materials

A paper published in Nature outlines some cutting-edge research that might help us to develop more resilient storage devices and increase the rate of AI processing of data sets. Antiferromagnetic (AFM) materials are resilient to magnetic interference, making them ideal for specific uses. Among the possible benefits of this new material subset include cryptocurrency mining, AI processing, and even space programs.

Most AI processing systems, from Siri to Alexa, to Netflix, utilize large data sets. They collect voice patterns, searches, and several other elements to provide better service to their clients. Yet as the data sets grow, the storage space and processing power needed to gain insights also rise exponentially. The development of AFM materials may provide a cost-effective way for these massive lakes of data to be processed more efficiently by AI agents.

The Current Paradigm in Big Data

The best current solution that businesses have for dealing with data lakes is physical or cloud storage. Both of these rely on, at their core, magnetic-based memory storage. They are naturally rapid and don't wear out through regular read/write cycles, making them ideal for an enduring data set. Since these massive businesses are such lucrative markets, the semiconductor manufacturers have spent billions over the last decade improving magnetic RAM (MRAM) processes to be more efficient. Unfortunately, today's MRAM systems are built atop ferromagnetic materials.

High-performance AI applications can utilize these MRAM modules, but they are far less efficient since they require large-capacity transistors just to supply data at the rate that the AI can process it. The bottleneck, therefore, is in the materials used to manufacture these MRAM modules. An additional bottleneck is that these MRAM modules take up significant space. Finally, the limitation in scaling these modules down comes from the impact of the ferromagnetic materials when magnetic fields become concentrated. As a result, the current density of MRAM models is the best we'll probably get through typical ferromagnetic material bases. Thus, research into AFM materials seems to be the best way forward. With more efficient materials at the base of these systems, we can scale them down in size more effectively.

The Savior of Future Computing

AFM materials demonstrate inherently faster dynamics than the ferromagnetic bases used to build contemporary MRAM modules. There are no macroscopic magnetic poles that allow AFM materials to perform well without magnetic fields interacting with the module's processes. Since AFMs can also be scaled down, they could theoretically form the basis for much smaller MRAM modules once the material becomes available. Most security officials will have already spotted another crucial benefit to AFM modules. Typical disk drives can be erased or corrupted through exposure to magnetic fields. AFM-based modules would have no such weakness since they wouldn't be affected by external magnets.

Building On the Success of the Past

In 2020, Tech Xplore mentioned an experiment that saw electrical writing of data onto an AFM chip-base. The device used platinum manganese (PtMn) to significantly reduce the size of the module and reduce the electrical current needed for a successful write cycle. What's more important, the module was the first ever built that was compatible with current semiconductor manufacturing processes. This breakthrough is significant because it means memory producers could use their existing equipment and techniques to start producing AFM MRAM modules en-masse.

The current research uses a new material, iridium manganese (IrMn3), to simplify the read and write processes. AFM materials typically have smaller read and write signals than their ferromagnetic competitors. The new design model utilizes six electrical terminals to increase efficiency - an improvement over the four terminals used in the 2020 experiment.

>What Should We Expect?

It's not a sure thing that AFM will be the future of data storage and processing, but the signs are promising. Without magnetic interference, we could see memory modules being shrunk down even further. In addition, modules for use in space become far more efficient since it doesn't have to worry about interference from background sources. The applications may vary significantly from one to another, but the underlying technology remains the same. Once manufacturers start adopting and fine-tuning the processes, we could see a significant change in how we consider mass storage devices.

Comments