Rotary engines were developed by Wankel of Germany in the 1930s. They never really gained acceptance in the mass market, aside from Mazda in its RX-7 and later models. But a project team says they can take the Mazda rotary engine block and build an aero engine around it that could be retrofitted to all aircraft - and it will change aviation.

The four-stroke piston engine technology used by the majority of planes in general aviation dates back 60 years.

There's nothing wrong in sticking with what works but those motors require 70 to 80 moving parts and still use 100-octane low-leaded (100 LL) fuel that has long been displaced by kerosene for commercial aircraft. There are some new advances in combustion chamber design and electronic management systems that are making it possible to develop a reliable rotary engine for small planes running on standard kerosene jet fuel.

The effort is called EUREKA project E! 2743 KERO and it came into being because Mistral Engines saw the demand for a safer, more reliable motor that could be easily adapted to any model of light aircraft and able to run on industry standard fuel.

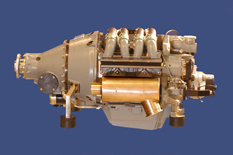

Safety and reliability most important in aviation. Advantages of the design include excellent reliability as there are few moving parts, a high power-to-weight ratio, compactness and smooth running compared with conventional piston-engine designs. Moreover, the engine will run on widely available standard commercial aviation fuels.

The Wankel engine has a rotor instead of reciprocating pistons, doing away with any need for crankshafts, pistons and springs and reducing the number of moving parts to only two or three. Modern electronics has now made it possible to overcome timing and injection control complications, resulting also in similar fuel consumption figures to piston engines.

Several partners are involved in the EUREKA project. The Ecole Polytechnique Fédérale de Lausanne (EPFL) is studying the best combustion conditions for the kerosene in terms of combustion-chamber design, injection and ignition. “We are also now developing a special exhaust silencer with the EPFL to limit the noise, using active and passive noise- reduction technologies able to work at very high temperatures,” adds Geles. “This has not been done before.”

Most of the technical problems have already been overcome – one problem still being tackled is pushing away the detonation, or pre-ignition, limit. Nevertheless, Geles predicts full FAA certification within 18 months of the project ending.

Comments