Coating the surface of nanoparticles in a responsive, active material could mean tailoring the size and shape of drug delivery capsules and have a dramatic effect on how a drug interacts with cells in the body. This ‘active matter’ could mark a turning point in the design of robots and make it possible to determine the shape, movement and behavior of a soft solid not by its natural elasticity but by human-controlled activity on its surface.

How it works

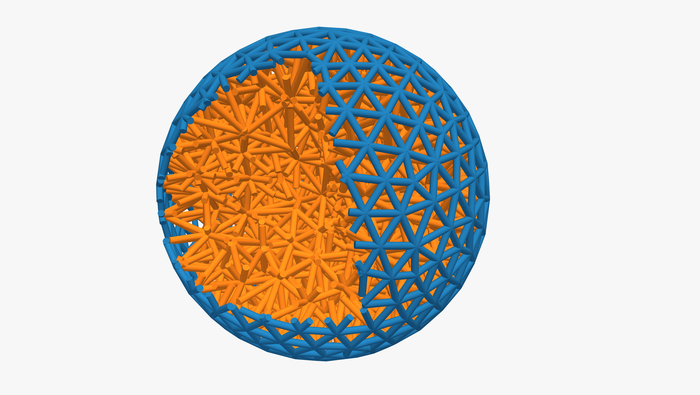

The surface of an ordinary soft material always shrinks into a sphere. Water beads into droplets because the surface of liquids and other soft material naturally contracts into the smallest surface area possible – i.e. a sphere. But active matter can be designed to work against this tendency. An example of this in action would be a rubber ball that’s wrapped in a layer of nano-robots, where the robots are programmed to work in unison to distort the ball into a new, pre-determined shape (say, a star).

Wrapping an elastic ball (orange) in a layer of tiny robots (blue) allows researchers to program shape and behavior. Credit: Jack Binysh

Such active matter will lead to a new generation of machines whose function will come from the bottom up. So, instead of being governed by a central controller (the way today’s robotic arms are controlled in factories), these new machines would be made from many individual active units that cooperate to determine the machine’s movement and function. This is akin to the workings of our own biological tissues, such as the fibers in heart muscle.

For the study, the researchers developed theory and simulations that described a 3D soft solid whose surface experiences active stresses. They found that these active stresses expand the surface of the material, pulling the solid underneath along with it, and causing a global shape change. The researchers found that the precise shape adopted by the solid could then be tailored by altering the elastic properties of the material.

In the next phase of this work – which has already begun – the researchers will apply this general principle to design specific robots, such as soft arms or self-swimming materials. They will also look at collective behaviour – for example, what happens when you have many active solids, all packed together.

Work on active matter challenges the assumption that the energetic cost of the surface of a liquid or soft solid must always be positive because a certain amount of energy is always necessary to create a surface. Dr Jack Binysh, study first author, said, “Active matter makes us look at the familiar rules of nature – rules like the fact that surface tension has to be positive – in a new light. Seeing what happens if we break these rules, and how we can harness the results, is an exciting place to be doing research.”

Comments