Though chemicals are most common, they are not always practical or portable. Ultraviolet radiation in the 200 to 300 nanometer range will destroy the virus, it just requires UV radiation sources that emit sufficiently high doses of UV light. Current devices are things like expensive mercury-containing gas discharge lamps, which require high power, have a relatively short lifetime, and are bulky.

The best solution is high-performance, UV light emitting diodes, but applying a current to them for light emission is complicated. The electrode material also has to be transparent to UV light. While finding transparent electrode materials operating in the visible spectrum for displays, smartphones and LED lighting is a long-standing problem, the challenge is even more difficult for ultraviolet light.

The current material solution commonly employed for visible light application is used despite it being too absorbing in the UV range, according to Joseph Roth, doctoral candidate in Materials Science and Engineering at Penn State, and co-author of a study which focused on a recently discovered new class of transparent conductors. When predictions pointed to the material strontium niobate, the researchers reached out to Japanese collaborators to obtain strontium niobate films and immediately tested their performance as UV transparent conductors. While these films held the promise of the theoretical predictions, the researchers needed a deposition method to integrate these films in a scalable way.

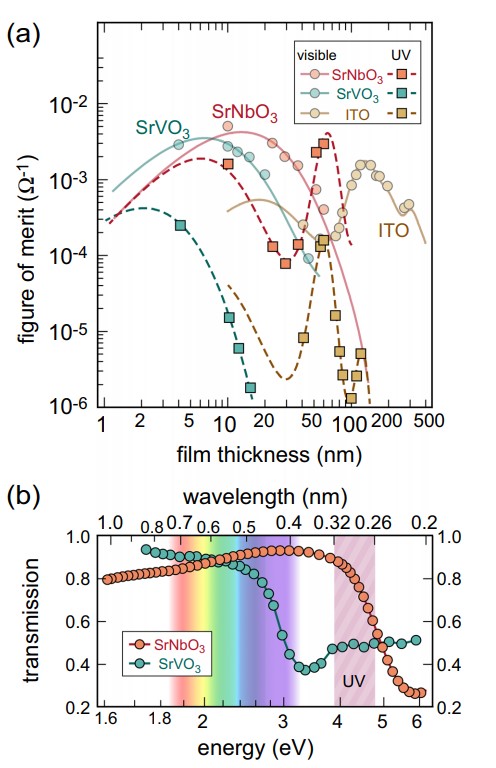

Comparison of transparent conductor performance. a Figure of Merit ΦTC vs. film thickness for transparent conductors SrNbO3, SrVO3, and indium–tin oxide (ITO) in visible range (400–700 nm, circles) and in the ultraviolet (UV) range (260–320 nm, squares). Experimental data for ITO and SrVO3 were calculated using data from55,70 and45, respectively. b Transmission of 10-nm-thick freestanding films of SrNbO3 and SrVO3. Rainbow color highlight the visible range, the shaded region labeled UV indicates the spectral range used to calculate figure of merit in the UV shown in a.

They grew the films using sputtering, the standard film-growth technique used by industry since the 1970s, and were successful. They believe that makes it possible to integrate this new material into UV LEDs at low cost and high quantity.

Originally, they focused on water disinfection but it could also offer a solution to deactivate COVID-19 in aerosols that might be distributed in HVAC systems of buildings, or even theaters, sports arenas and public transportation vehicles.

Comments