A collaboration among the Mahou and Createch Co., Universidad Politécnica de Madrid (UPM) and the Institute of Materials Science and the Institute of Catalysis and Petrochemistry of Consejo Superior de Investigaciones Científicas (CSIC), has developed biocompatible materials to be used as support for bone regeneration from bagasse (residue) left over after beer brewing. Bagasse is constituted by organic waste from malt, never experiencing modifications afterwards. This is the reason why bagasse is considered a subproduct, commonly used to make fodder and it is inexpensive. The resulting new materials are an alternative to prosthetic material made from processed sheep bones or expensive synthetic materials.

The waste obtained from the beer brewing process contains the main chemical components found in bones (phosphorus, calcium, magnesium and silica), that after undergoing modification processes, this waste can be used as support or scaffold to promote bone regeneration for medical applications such as coating prosthesis or bone grafts. Waste usage from the food industry is a great source of raw material recovery because it is rich in chemical diversity and it can reduce the impact generated by the accumulation of waste in the environment.

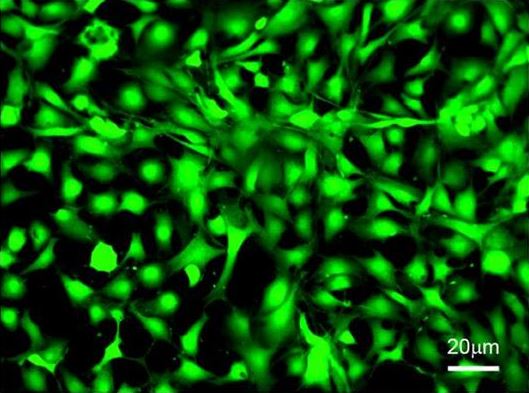

Mouse osteoblasts growing over 3D matrixes developed from food industry waste. Credit: Milagros Ramos and Ana Martínez Serrano, CTB-UPM

So far, the usage of synthetic materials as bone substitutes is the most used therapy for treatment of bone diseases. The therapeutic strategies are based on stiff porous scaffolds made of biocompatible materials to be used as molds. These molds will provide mechanical stability and will promote the growth of the new bone tissue that helps its regeneration.

The synthetic calcium phosphates are frequently used as matrices and coatings for orthopedic implants because of their resemblance to the composition of a bone. These materials are often obtained through chemical reactions of complex synthesis that use toxic reagents (for example benzoyl peroxides benzene and aniline) and calcinations at high temperatures close to 1500 ° C. As a result of this process, we obtain bioceramics but just after adding silicon through the hydrolysis of TEOS and sintering over 1,100 ° C.

The billing of the brewing sector was €2,990 million in 2012, almost covering completely the total production of malt and hops in the country. The most common products in the production process are bagasse, yeast and malt dried residues.

Biomaterial used as a matrix for bone regeneration and made by a porous block of 1 cm height which was obtained from the beer bagasse treatment. Credit: Angeles Martín Luengo, Malcolm Yates and Eduardo Sáez, ICMM-CSIC and ICP-CSIC

The treatments applied to bagasse residue in this research give as a result a new material rich in silicon, phosphorus, calcium and magnesium. The analysis of this new material shows the presence of interconnected pores of between 50 and 500 microns in diameter which is similar to the porosity of cancellous bone. All this would facilitate the complete vascularization after the bone implant.

A first approach using cell cultures has established the biocompatibility of the materials by analyzing the cell viability of cultured osteoblasts in the presence of powder materials components. Then, after compacting and sintering the materials that became 3D solid matrixes, the ability of bone-like cells to adhere to these materials were analyzed.

Also, researchers analyzed how these materials proliferate and distinguish from the mature bone cells which are able to express typical markers of bone phenotype such as alkaline phosphatase and to conduct the collagen synthesis and mineralization of the extracellular matrix.

Citation: SÁEZ ROJO, E; RAMOS, M; YATES, M; MARTÍN-LUENGO, MA; MARTÍNEZ SERRANO, AM; CIVANTOS, A; LÓPEZ-LACOMBA, JL; REILLY, G; VERVAET, C; TARTERRA, JL; FITE LB; VEGA ARGOMANIZ, L. “Preparation, characterization and in vitro osteoblast growth of waste-derived biomaterials”. RSC Advances 4 (25): 12630-12639. DOI: 10.1039/c3ra47534d. Pub 2014.

Comments