The future of vaccines looks a little different. The race is on to create a universal flu vaccine, one that does not have to be recreated each year, and to also bring the technology cost down to where it is more financially constructive to get people a vaccine than have them in the hospital.(2)

I was intrigued that around the time of the movie "Contagion" a company named Medicago issued a statement about plant-based technology and its Virus-Like Particles (VLPs). Why did it catch my attention? They have created a vaccine and antibody production system based on transient protein expression in tobacco.

That's right, evil tobacco can save lives. In the 1950s, tobacco could do no wrong - even doctors were in advertising campaigns.

By the 1980s, though, cultural mullahs were blaming tobacco for everything - the scientization of cultural politics had swung to the other side and that's where it remains today, unless you think a serious case can be made for third hand smoke causing cancer.

Smoking is still bad for you but it might be time for the reputation of tobacco to be rehabilitated a little. And I wanted to learn a little something about vaccine production too, so I got on the phone with Andy Sheldon, Chief Executive Officer of Medicago, the company behind the make-vaccines-from-tobacco technology.

The first question I had was, why tobacco? The name Medicago sounds like Medicago sativa, the name of the Alfalfa plant, which was discovered in ancient Persia and means "sowed by the Medians" so tobacco doesn't follow naturally from that. The original work of Dr. Louis-Philippe Vézina (now Chief Scientific Officer at Medicago) while at Agriculture and Agri-Food Canada, he explained, was with Alfalfa. Because it is transgenic, requiring modification of the DNA, it was suitable for recombinant proteins like might be used in biofuels but they had some other ideas in the area of vaccines. In 2004 they began working with tobacco because it is instead transient. "We were looking for a very fast response once we got a genetic sequence into a plant and that's what we got from tobacco." Mystery solved!

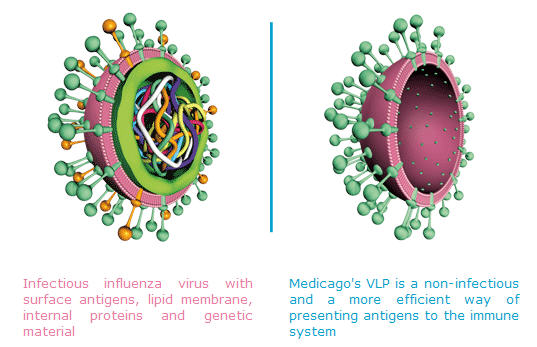

Their transient expression manufacturing platform, working with tobacco leaves, means they can be timely and cost-effective, cheaper than egg-based vaccines and much cheaper than cell cultures and faster response than both. Vaccines are the new golden opportunity in pharmaceuticals, the market is growing, so I asked why we still primarily use 1950s methods to make them. "The pathway from research to licensure is long and expensive. That's probably the big reason why it takes a degree of time for new vaccine technologies to work their way through a financial pipeline and be made available," he said. If it's not broke, maybe it doesn't need to be fixed? I can understand that reasoning. But Their Virus-Like Particles (VLPs) technology is something new and it's basically better; the VLPs are protein shells with offshoots that look like the disease so the body's immune system goes to work on them but it lacks the core genes so VLPs are non-infectious. They also don't need a sample of the virus to make a vaccine, just the genetic sequence. That's good science.

VLP-based vaccines have also been shown to protect against different strains of a virus so the mutation of an influenza virus each year becomes less of an issue and there is less wasted vaccine if a pandemic that is anticipated never breaks out.

Their ideas have gotten the right support. Creating great technology is one thing - building a manufacturing facility is another. And in vaccines, you have to have your own site and that means big money. "You always want to try and build your manufacturing where you will do your Phase III, so you are faced with a dilemma; you have choices like partnering but the cost is why you see so many companies exit at that point."

Traditional pharmaceutical manufacturing is expensive - up to a billion dollars to make a new site. Medicago has two advantages that make that cost more reasonable; they use tobacco leaves so the raw materials are cheap and the government would like a better way to do vaccines too. They were able to partner with Alexandria Real Estate Equities for the facility itself - Alexandria specializes in life sciences properties - and DARPA was willing to put up half the money if they could show an ability to produce 10 million doses of an influenza vaccine in one month.

New strains of influenza take months to analyze and produce vaccines. Governments are also always concerned about pandemics like H5N1, the avian flu, as well. In a real pandemic, the legacy way of infecting embryos of fertilized eggs and then incubating it and extracting it takes far too long. Medicago says they can deliver a vaccine for testing three weeks after they get the genetic sequences from a pandemic strain.

Here's hoping we never have to find out but it's good to know vaccine production is moving into the 21st century just the same.

NOTES:

(1) Former President Bush - you remember him, the guy who supposedly hated science while he doubled funding for the NIH - proposed and got Congress to sign off on $3.3 billion for cell-based manufacturing in 2006, to try and wean us off eggs for vaccines.

(2) If you want to try and make your own vaccine, PBS has this little flash utility and you can give it a try.

Comments