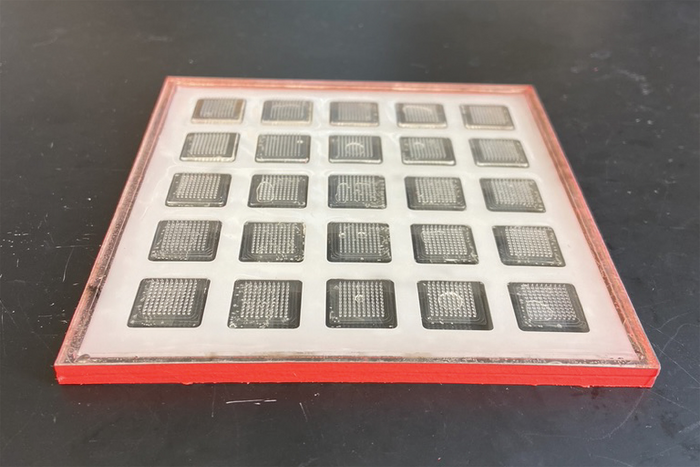

The printer produces patches with hundreds of microneedles containing the vaccine. The patches can be attached to the skin, allowing the vaccine to dissolve without the need for a traditional injection. Once printed, the vaccine patches can be stored for months at room temperature.

In their paper, the scientists used the printer to produce thermostable Covid-19 RNA vaccines that could induce a comparable immune response to that generated by injected RNA vaccines, in mice.

Credit: MIT

Most vaccines, including mRNA vaccines, have to be refrigerated while stored, making it difficult to stockpile them or send them to locations where those temperatures can’t be maintained. Furthermore, they require syringes, needles, and trained health care professionals to administer them. Before Covid-19 arrived, efforts were on to build a device that could quickly produce and deploy vaccines during outbreaks of diseases such as Ebola. Instead of producing traditional injectable vaccines, the researchers decided to work with patches about the size of a thumbnail, which contain hundreds of microneedles. Such vaccines are now in development for many diseases, including polio, measles, and rubella. When the patch is applied to the skin, the tips of the needles dissolve under the skin, releasing the vaccine.

The “ink” that the researchers use to print the vaccine-containing microneedles includes RNA vaccine molecules that are encapsulated in lipid nanoparticles, which help them to remain stable for long periods of time.

The ink also contains polymers that can be easily molded into the right shape and then remain stable for weeks or months, even when stored at room temperature or higher. The researchers found that a 50/50 combination of polyvinylpyrrolidone and polyvinyl alcohol, both of which are commonly used to form microneedles, had the best combination of stiffness and stability.

Inside the printer, a robotic arm injects ink into microneedle molds, and a vacuum chamber below the mold sucks the ink down to the bottom, making sure that ink reaches all the way to the tips of the needles. Once the molds are filled, they take a day or two to dry. The current prototype can produce 100 patches in 48 hours, but the researchers anticipate that future versions could be designed to have higher capacity.

To test the long-term stability of the vaccines, the researchers first created an ink containing RNA that encodes luciferase, a fluorescent protein. They applied the resulting microneedle patches to mice after being stored at either 4 degrees Celsius or 25 degrees Celsius (room temperature) for up to six months. They also stored one batch of the particles at 37 degrees Celsius for one month.

Under all of these storage conditions, the patches induced a strong fluorescent response when applied to mice. In contrast, the fluorescent response produced by a traditional intramuscular injection of the fluorescent-protein-encoding RNA declined with longer storage times at room temperature.

Then, the researchers tested their Covid-19 microneedle vaccine. They vaccinated mice with two doses of the vaccine, four weeks apart, then measured their antibody response to the virus. Mice vaccinated with the microneedle patch had a similar response to mice vaccinated with a traditional, injected RNA vaccine.

The researchers also saw the same strong antibody response when they vaccinated mice with microneedle patches that had been stored at room temperature for up to three months. While this study focused on Covid-19 RNA vaccines, the researchers plan to adapt the process to produce other types of vaccines, including vaccines made from proteins or inactivated viruses.

Comments