The research was done by scientists at the Air Force Research Laboratory Materials and Manufacturing Directorate (AFRL/RX), with Plextronics, Inc., and the Pennsylvania NanoMaterials Commercialization Center, both located in the City of Champions, Pittsburgh, PA.

The ready-to-use, technology captures sunlight and stores it as energy to power Global Positioning System components, portable communications, and other devices for U.S. soldiers.

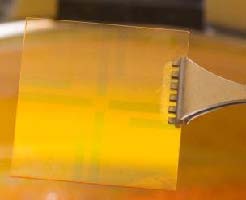

Plexcore technology allows solar cells to form-fit soldiers’ uniforms to power GPS components and communication devices, and could also be used to “print” solar panels onto thin films incorporated into military tents. Commercial applications include solar energy batteries for cell phones, radios, and other portable devices. Credit: U.S. Air Force photo

According to 2nd Lt. Christopher A. Vaiana of the Directorate's Nonmetallic Materials Division, AFRL/RX provided guidance and funding to develop a special "conductive ink" that can be used to make printed organic photovoltaic solar cell panels on very thin, flexible surfaces using ink-jet printing. This new technology, called Plexcore, allows solar cells to form-fit soldiers' uniforms. It can also be used to print solar panels onto thin films in military tents, Lieutenant Vaiana said.

The agreement between AFRL/RX and the Commercialization Center includes the development of a technology roadmap identifying technologies AFRL/RX needs and is interested in funding. The Center is responsible for reporting these needs to industry and requesting proposals. Next, a team of personnel representing both organizations carefully examines the proposals and indentifies those with the most promise to receive funding, Lieutenant Vaiana explained.

The agreement has already resulted in the successful program with Plextronics, whose primary focus is organic solar cell and organic light emitting diodes, and more specifically, the conductive inks and process technologies that enable such applications, he pointed out.

"Solar power and solid-state lighting offer substantial promise as approaches toward the development of practical alternative energy technology," Lieutenant Vaiana stated. "Combined with the low-cost manufacturing methods of printed electronics, solar and solid-state lighting panels could become economical and environmentally compatible solutions to current day and future energy challenges.

Plexcore has advantages over today's silicon-based solar cell panels, including cost reduction: approximately $50 per square meter versus $500 per square meter for silicon-based panels, Lieutenant Vaiana explained.

"The technology has won best-in-class recognition for unmatched solar power efficiency. The research and development effort has also helped streamline the manufacturing process for printed OPV devices, resulting in reduced costs and trimmed production times. Compared to other organic photovoltaic materials, Plexcore offers world-class efficiency," he said.

Comments